Details

HEAVY DUTY 1000KG DIY SINGLE AXLE BOAT TRAILER KIT

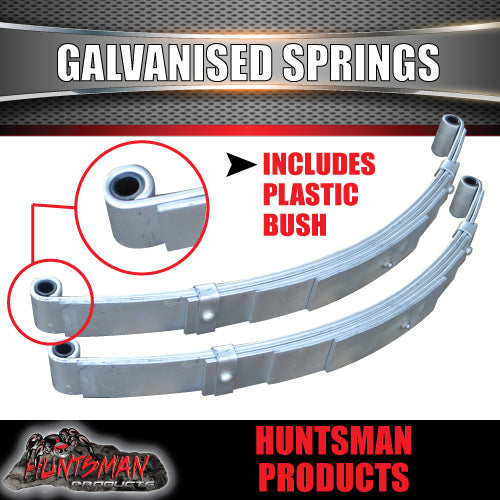

EYE TO EYE SPRINGS

40MM STUB AXLES TO SLEEVE INTO 50MM RHS

STUD PATTERNS AVAILABLE

FORD (5/114.3 PCD, 1/2" STUDS AND NUTS)

COMMODORE (5/120 PCD, 7/16" STUDS AND NUTS)

HQ (5/120.65 PCD, 7/16" STUDS AND NUTS)

HT (5/108 PCD, 7/16" STUDS AND NUTS)

6 STUD L/C (6/139.7 PCD, 1/2" STUDS AND NUTS) +$20

5 STUD L/C (5/150 PCD, 9/16" STUDS AND NUTS) +$20

IN THIS KIT

2X 40MM X 200MM STUB AXLES WITH SPLIT PINS AND CASTLE NUTS TO SUIT LM BEARINGS (SUITED TO SLEEVE INTO 50MM BOX STEEL)

2X GALVANISED DACROMET HUBS. S.G CASTING (CUPS ALREADY INSERTED INTO DRUMS)

2X LM BEARING KITS INCLUDING DUST SEALS AND DUST CAPS (MARINE SEALS)

ALL WHEEL NUTS TO SUIT STUD PATTERN SUPPLIED

2X 5 LEAF DACROMET 60MM EYE TO EYE SPRINGS. RATED 1300KG PER PAIR (SPRINGS ARE SHOT PEENED FOR EXTRA STRENGTH)

2X FRONT 60MM HANGERS

2X REAR 60MM SHACKLE HANGERS WITH DOUBLE STRENGTH WELDED PLATES

2X 9/16" FRONT HANGER BOLTS, NUTS AND WASHERS

2X DOUBLE 5/8" HIGH TENSILE GREASABLE REAR SHACKLE BOLTS

2X GALVANISED FISH PLATES

4X GALVANISED 50MM X 130MM 1/2" U BOLTS WITH NUTS AND WASHERS

2X GALVANISED AXLE PADS

1X 2000KG GALVANISED 50MM BALL COUPLING (CTA APPROVED)

1X WELD ON COUPLING PLATE

3X HIGH TENSILE COUPLING BOLTS AND NYLOC NUTS

On ordering please supply your stud pattern and axle length?

EXTRAS AVAILABLE

JAPANESE MANUFACTURED BEARINGS $50 (CLICK ON LINK BELOW)

"CLICK HERE TO UPGRADE TO JAPANESE MANUFACTURED BEARINGS"

DACROMET®

DACROMET®, is the leading inorganic coating commonly specified in the wind turbine, heavy truck, marine, agricultural, construction equipment and aerospace industries. A water-based, VOC-compliant coating, DACROMET® is comprised mainly of overlapping zinc and aluminum flake in an inorganic binder.

SHOT PEENING

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals and composites. It entails impacting a surface with shot with force sufficient to create plastic deformation. Shot peening is often called for in aircraft repairs to relieve tensile stresses built up in the grinding process and replace them with beneficial compressive stresses.