Details

DIY SINGLE AXLE TRAILER KIT.

750KG RATING.

JAPANESE BEARINGS

STUD PATTERNS AVAILABLE

FORD (5/114.3 PCD, 1/2" STUDS AND NUTS)

COMMODORE (5/120 PCD, 7/16" STUDS AND NUTS)

HQ (5/120.65 PCD, 7/16" STUDS AND NUTS)

HT (5/108 PCD, 7/16" STUDS AND NUTS)

6 STUD L/C (6/139.7 PCD, 1/2" STUDS AND NUTS) +$20

5 STUD L/C (5/150 PCD, 9/16" STUDS AND NUTS) +$20

6 STUD D40/NP300 (6/114.3 PCD, 1/2" STUDS AND NUTS) +$20

5 STUD SUZUKI / F100 (5/139.7, 9/16" STUDS AND NUTS) +$20

AXLE LENGTHS AVAILABLE

1525MM (60") TIP TO TIP (1425MM HUB FACE TO HUB FACE)

1600MM (63") TIP TO TIP (1500MM HUB FACE TO HUB FACE)

1625MM (64") TIP TO TIP (1525MM HUB FACE TO HUB FACE)

1650MM (65") TIP TO TIP (1550MM HUB FACE TO HUB FACE)

1675MM (66") TIP TO TIP (1575MM HUB FACE TO HUB FACE)

1700MM (67") TIP TO TIP (1600MM HUB FACE TO HUB FACE)

1725MM (68") TIP TO TIP (1625MM HUB FACE TO HUB FACE)

1750MM (69") TIP TO TIP (1650MM HUB FACE TO HUB FACE)

1955MM (77") TIP TO TIP (1855MM HUB FACE TO HUB FACE)

2005MM (79") TIP TO TIP (1905MM HUB FACE TO HUB FACE)

IN THIS KIT

1X ROUND BARE AXLE 60, 63, 64, 65, 66, 67, 68, 69, 77, 79 INCH OVER ALL LENGTH AVAILABLE. ( IF YOUR NOT SURE ON THE SIZE YOU NEED THEN SEND US A MESSAGE FOR ADVISE)

2X 4 LEAF 45MM BLACK SLIPPER SPRINGS WITH NYLON BUSHES (SPRINGS ARE SHOT PEENED FOR EXTRA STRENGTH)

2X 1/2"SPRING BOLTS WITH SPRING WASHERS AND NUTS

2X FRONT SLIPPER HANGERS

2X REAR SLIPPER HANGERS

2X FISH PLATES

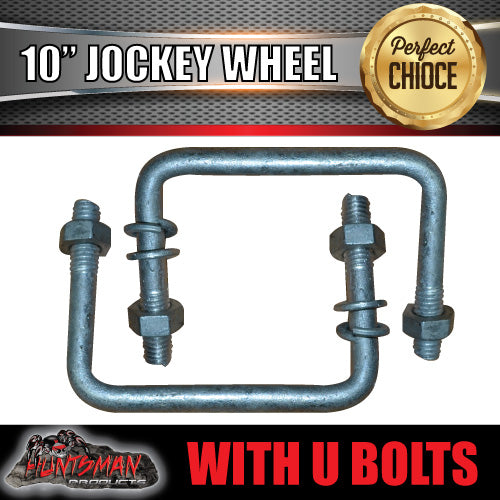

4X 39MM ROUND U BOLTS WITH SPRING WASHERS AND NUTS

2X AXLE PADS

2X 5 STUD HUBS WITH CUPS ALREADY PRESSED IN. HUBS MADE FROM SG CAST WHICH IS MUCH STRONGER THEN GREY IRON

2X LM JAPANESE KOYO HOLDEN BEARING SETS (2X LM INNER BEARINGS, 2X LM OUTER BEARINGS, 2X WASHERS, 2X SPLIT PINS, 2X DUST SEALS, 2X DUST CAPS)

1X UNIVERSAL 2/3 HOLE 50MM 2000KG BALL COUPLING

1X WELD ON COUPLING BASE PLATE

3 X HIGH TENSILE COUPLING BOLTS WITH NYLOC NUTS

ON PURCHASING PLEASE PROVIDE YOUR AXLE LENGTH AND STUD PATTERN

EXTRAS AVAILABLE

2" OR 4" DROP AXLE $295, DROP AXLES APPROX. 5 DAYS TO ENGINEER

ASSEMBLE OF AXLE $50

SHOT PEENING

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals and composites. It entails impacting a surface with shot with force sufficient to create plastic deformation. Shot peening is often called for in aircraft repairs to relieve tensile stresses built up in the grinding process and replace them with beneficial compressive stresses.