Details

DIY TANDEM TRAILER 2000KG KIT

ROCKER ROLLER SPRINGS, HYDRAULIC DISC BRAKES, STUB AXLES.

SUITED TO OVERLAY AXLES

STUD PATTERNS AVAILABLE

FORD (5/114.3 PCD, 1/2" STUDS AND NUTS)

COMMODORE (5/120 PCD, 7/16" STUDS AND NUTS)

HQ (5/120.65 PCD, 7/16" STUDS AND NUTS)

HT (5/108 PCD, 7/16" STUDS AND NUTS)

6 STUD L/C (6/139.7 PCD, 1/2" STUDS AND NUTS) + $105 (12" DISCS)

5 STUD L/C (5/150 PCD, 9/16" STUDS AND NUTS) +$105 (12" DISCS)

IN THIS KIT

2X 45MM X 250MM SQUARE STUB AXLES WITH HYDRAULIC DISC MOUNTS WELDED TO STUBS. 1400KG RATED PER PAIR

2X 45MM X 250MM STUB AXLES WITH CASTLE NUTS AND WASHERS

2X HYDRAULIC BRAKE CALIPERS WITH STAINLESS STEEL PISTONS AND CERAMIC BRAKE PADS.

2 X 10" DISC HUBS WITH SLIMLINE BEARING KITS.

2X LAZY HUBS WITH SLIMLINE BEARING KITS

ALL WHEEL NUTS TO SUIT STUD PATTERN SUPPLIED

1X 5 LEAF 2.5 TONNE ROCKER ROLLER LOAD SHARING SPRING SET WITH ALL GREASABLE SHACKLES AND HANGERS ALREADY ASSEMBLED (SPRINGS ARE SHOT PEENED FOR EXTRA STRENGTH)

4X UNIVERSAL FISH PLATES

8X 45MM X 150MM SQUARE 1/2" U BOLTS

4X AXLE PADS

16X SPRING WASHERS AND NUTS FOR U BOLTS

1X 2000KG OVERRIDE BALL COUPLING

1X 3/4 MASTER CYLINDER BRACKET

1X 3/4 MASTER CYLINDER WITH MOUNT BOLTS

1X 4 HOLE COUPLING WELD ON PLATE

4X HIGH TENSILE COUPLING BOLTS AND NYLOC NUTS

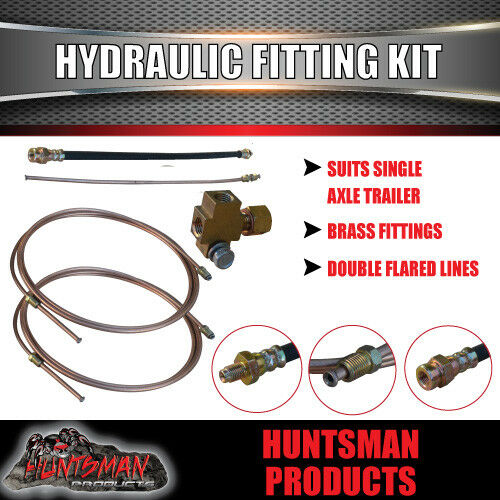

1X 2500MM COUPLING TO AXLE MAIN FLARED BUNDY LINE WITH NUTS (LET US KNOW IF LONGER IS REQUIRED)

1X 1500MM FLARED BUNDY LINE WITH NUTS

1X 500MM FLARED BUNDY LINE WITH NUTS

1X BRASS T PIECE

1X MASTER CYLINDER NUT AND WASHER

ALL COPPER FITTINGS AND T PIECES TO COMPLETE AXLE AND FINISH OFF AT COUPLING WITH PRE FLARED LINES!!

Please check coupling to axle hydraulic line length. if longer is required please get in contact with us

ON PURCHASING PLEASE PROVIDE YOUR STUD PATTERN ?

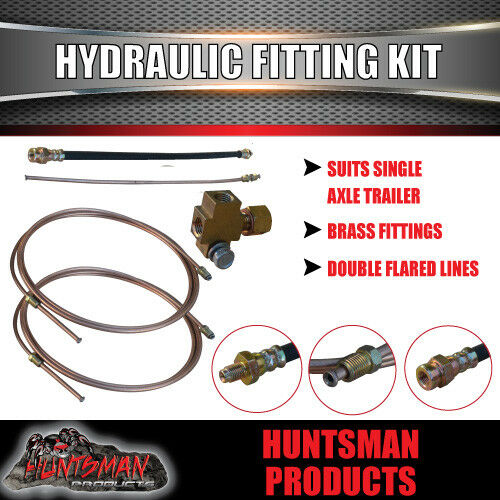

upgrade to the easy instillation hydraulic line setup.

12ft set up: $70 (CLICK ON LINK BELOW)

16ft set up: $75 (CLICK ON LINK BELOW)

"UPGRADE TO 12FT FULL FLEXI KIT BY CLICKING HERE"

"UPGRADE TO 16FT FULL FLEXI KIT BY CLICKING HERE"

UPGRADE TO JAPANESE BEARINGS $100.0 (CLINK ON LINK BELOW)

"CLICK HERE TO UPGRADE TO JAPANESE MANUFACTURED BEARINGS"

SHOT PEENING

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals and composites. It entails impacting a surface with shot with force sufficient to create plastic deformation. Shot peening is often called for in aircraft repairs to relieve tensile stresses built up in the grinding process and replace them with beneficial compressive stresses.